As a company that makes a living from maritime distribution, safe navigation is always the foundation of our activities and the most important of our various responsibilities to society today and in the future.

In the ten years since the merger, the Company has increased the size of the fleet and focused on maintaining and improving safe operations as well as environmental protection. As a result, we have achieved a certain outcome, including lower ship stoppage rates.

In order to continue accident-free operations, we will work together on land and sea to pursue the best safety management methods while responding to changes in the environment.

Safety Management System

We have established safety management systems for providing shipping services. Under these systems, the SMS Management Committee holds an annual meeting to share relevant information, principally: improvement proposals from vessels under our management; statistics on accident occurrences; internal audit results for vessels under our management and the ship management division; and reports on issues identified through external vessel inspections, such as by Post State Control (PSC), RightShip, and the Ship Inspection Report (SIRE) Programme adopted by oil majors. Findings from the above activities are reflected in the safety management systems, a key vessel management function, in order to ensure ongoing improvement of the Company's overall safety and quality control system.

Thorough Management of Safe Operations

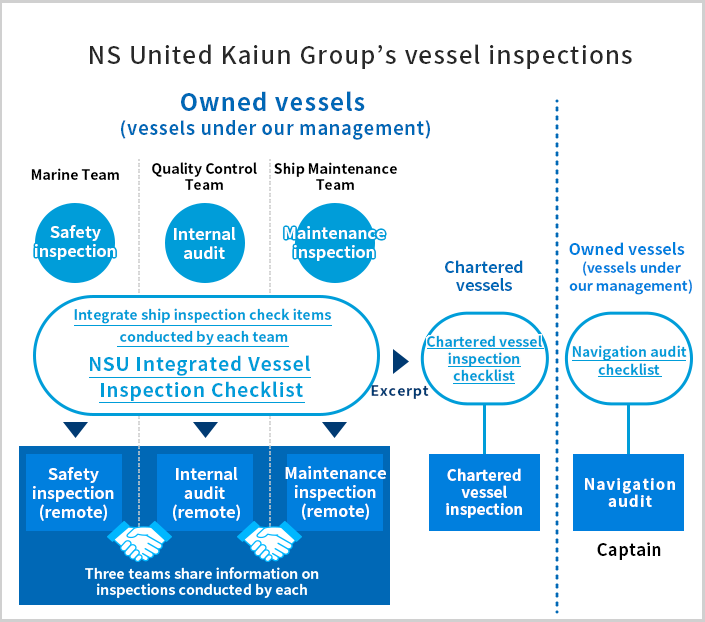

Our vessel inspections are conducted both by persons sent from the head office (remotely as needed to prevent the spread of COVID-19) and by onboard personnel, in order to ensure safe navigation management.

Inspection of Vessels under Our Management

We conduct three types of inspections for vessels under our management.

- Internal audit:Conducted by the Company's internal auditors once a year to check for compliance with safety management systems on vessels under our management.

- Safety inspection:Conducted by the superintendents of the Company's Marine Team for vessels under our management.

- Maintenance inspection:Conducted by the superintendents of the Company's Ship Maintenance (Engineering) Team for vessels under our management.

As a measure to prevent the spread of COVID-19, we developed a remote vessel inspection system that mainly uses photographic evidence, as an alternative to on-site inspections made by superintendents visiting each vessel, and started to apply the system officially from fiscal year 2020.

Remote vessel inspections use the NSU Integrated Vessel Inspection Checklist, which consists of about 380 check items resulting from consolidation of the audit and inspection checklists used by each team. This tool is applicable to all types of audit and inspection processes for our fleet, thus helping improve operational efficiency and establish information sharing system.

Inspection of Our Chartered Vessels

In order to fulfill our responsibility to the Group's customers (shippers) for controlling and maintaining the quality of marine transportation services, we conduct inspections of our chartered vessels. By ensuring the safe navigation of such vessels, we provide better services to our customers as well as society.

Inspections are performed based on the checklist and at appropriate intervals following requests from operators. Depending on the inspection results, we offer shipowners and vessel management companies suggestions for necessary improvement. Conducting inspections for chartered vessels on an ongoing basis, we aim to ensure that NS United Kaiun will have closer communication with shipowners and vessel management companies, which will encourage efforts by each party to improve the level of navigation safety.

Navigation Audit Conducted by the Captain

The captain conducts onboard audit (vessel inspection) within about one month from boarding. The checklist used for navigation audits focuses on the bridge area (navigation-related matters) while also including the assessment of all officers' skills. Onboard audits (vessel inspections) performed by the captain shortly after boarding help them understand the conditions of navigational instruments and various other onboard equipment as well as determine the skills of crewmembers.

Accident Prevention Systems

We classify accidents with respect to the possibility of recurrence and risk level, and take measures based on the classification. In addition, in order to prevent possible accidents, we look into near-miss incidents, and take measures with the cooperation of external stakeholders.

Accident Zero Achievement Committee

The Accident Zero Achievement Committee analyzes the causes of accidents that have occurred for vessels managed by the Company, looking in detail at both physical/hardware aspects and systemic or “soft” aspects. The committee also analyzes the causes in chronological order and examines preventive measures.

The results of accident cause analysis and recurrence prevention measures are also reported to each ship's site to help realize 0 accidents.

Incident Investigation Committee

For incidents that have occurred on vessels under our management which are determined to have a high risk and are likely to recur in the future, an in-house Incident Investigation Committee has been set up to conduct detailed analysis to determine the cause of the incident and prevent its recurrence.

Near-miss Reporting

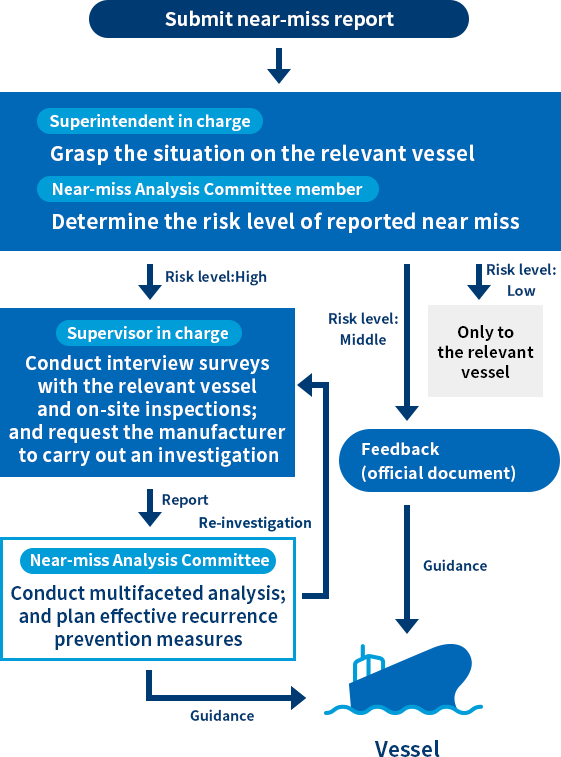

We have established the near-miss reporting system, which requires individual vessels to report near-miss incidents, in order to eliminate the risk of potential accidents.

The Near-miss Analysis Committee reported incidents to determine the cause, and plans effective recurrence prevention measures to be shared with all vessels under our management. Also, a collection of other near-miss incidents is created to be distributed across the vessels as a guidance for preventing similar cases.

Near-miss reports submitted from vessels are divided into two groups by risk level, and the group of near-miss reports with a higher risk level are subject to in-depth analysis. Receiving reports, the superintendent in charge first conducts hearing with the relevant vessel and requests the manufacturer to carry out an investigation, and then reports to the Near-miss Analysis Committee.

Reinforcement of Accident Response

The NS United Kaiun Group regularly holds emergency response drills with simulated marine accidents. We hold company-wide drills every year.

Once every two years, we invite external parties (members of the shipping media, insurance companies, etc.) to participate in large-scale drills, including mock (simulated) press conferences.

Drills are based on the scenario of an accident involving an oil spill from a vessel, enabling participants to confirm the emergency procedures used to minimize marine pollution.

In fiscal year 2021, we held a training session based on the scenario of one of our chartered vessels suffering a grounding accident, with the full cooperation of domestic friendly owners of our chartered vessels, which is the first time we have organized such a session. We will continue with these training activities together with internal and external parties, including our business partners, so that we will be able to take prompt and appropriate action in the event of accidents involving any vessels we operate.

Hybrid (remote/in-person) emergency response drill

Mock press conference

Holding Safety Meetings with Shipowners

Our fleet is composed of our owned vessels and chartered vessels. In FY2021, the Company started to hold a safety meeting with ship-owners in response to the recent occurrence of marine casualties and incidents as well as increasing requirements of shippers for safety. The conference is attended by ship-owners for the Capesize Group, which is in charge of the Company's largest fleet segment, and the sales and safety management divisions.

Instead of unilaterally asking shipowners for excessive cooperation in our initiatives, we describe casualties and incidents that occurred on our vessels and measures to prevent recurrence, and exchange opinions with each of the participating companies in a sincere, frank manner. These activities will help raise the awareness and quality of safety for our entire fleet.

DX Promotion

In fiscal year 2021, we started to review and update software for the vessel management used by the ship management division, and vessels under our management. The plan is to make an upgrade from the existing Word and Excel-based packages by introducing more multifunctional and easier-to-operate programs, which is expected to improve operational efficiency and reduce workloads.

We are also looking to utilize data collected using the new vessel management software for the purpose of safe navigation and environmental conservation. Specific plans are to use data related to past hull and machinery trouble to develop measures to prevent incidents and trouble , for more reliable safety management.