Marine Pollution Control

Establishing Safe Navigation Systems

Improving Safe Navigation Management Quality

Preventing On-deck Oil Spills

Deck operations have the potential risk of causing accidental oil spills, particularly in association with on-deck hydraulic equipment and oil supply work. As a measure to prevent on-deck oil spillage, we ensure that all scuppers of vessels are closed while in port. In addition, deck rainwater is collected in tanks to prevent rainwater from draining away from the deck.

Proper Management of Onboard Waste

Various kinds of waste are generated by the crew living on board. We establish onboard waste management plans in compliance with MARPOL 73/78, and dispose of all onboard waste on shore, excluding food wastes, cargo residues not harmful to the marine environment, and other items specified as exceptions.

We establish garbage management plans for our vessels, according to which generated waste is separated into 13 types to be able to respond to the requirements of each port for waste sorting and recycling. We also take a number of waste reduction measures, such as minimizing combustibles by burning them using incinerators capable of reducing dioxin emissions, and installing can crushers.

Proper Management of Onboard Sewage

Onboard sewage is discharged from bathrooms and other facilities used by the crew living on board, and it is treated properly as on shore, where sewage undergoes microbial treatment or other processes at sewage treatment facilities. Our vessels are equipped with sewage treatment systems that are compliant with international standards stipulated by the IMO, and discharge properly treated sewage into nearshore waters.

Initiatives for Ship Recycling

Old ships are sent to scrap yards for ship recycling, where steel scrap and machinery parts are recovered for re-use and recycling. Many scrap yards for ship recycling are located in developing countries, and problems with the operation of these yards related to occupational health, safety and environmental pollution have come to international attention. In response to this issue, the Ship Recycling Convention was adopted at the IMO in 2009, and will enter into force in June 2025. In preparation for the Convention to enter into effect, we have prepared the inventory of hazardous materials (IHM)―information of hazardous substances aboard the ship that specifies the estimated amount and location of use―for each vessel, as a measure to ensure proper control of such substances.

Biodiversity Conservation

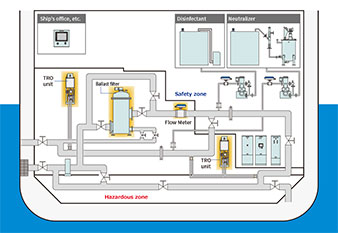

Proper Management of Ballast Water

Ballast water is potentially taken in one ocean region and discharged in another region, and as such, the water discharge contains exotic aquatic species that can have adverse impact on local aquatic ecosystems. To address this issue, we strive for proper management of ballast water, chiefly through exchange of ballast water in the open sea and use of ballast water treatment systems. We are introducing these systems in our vessels in sequence according to the Ballast Water Management Convention.

Progress of the plan for installing ballast water treatment systems (including future schedule)

| 2022 | 2023 | 2024 |

|---|---|---|

| 90% | 98% | 100% |

Note: Vessels owned by the Company

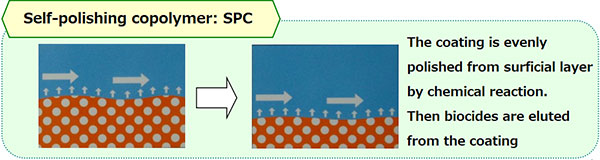

Antifouling Paint

In order to prevent aquatic organisms from moving due to hull attachment and adversely affecting the ecosystem, our vessels are docked periodically for hull cleaning and application of environmentally friendly antifouling paint. These measures also bring about a hull surface-smoothing and drag-reducing effect, leading to fuel conservation and CO2 emissions reduction.

Image provided by: Nippon Paint Marine Coatings Co., Ltd.

Hull Fouling Control

In order to prevent trans-boundary movements of aquatic organisms adhered to the hull which may affect the ecosystem adversely, the IMO adopted the Guidelines for inspection of anti-fouling systems on ships in 2011, which sets forth appropriate maintenance measures, such as application of anti-fouling paint, to be taken for ships. We have established proper anti-fouling management plans in compliance with the Guidelines, and carry out measures as necessary, including underwater hull inspections and cleaning in addition to application of anti-fouling paint.

Air Pollution Control

Response to SOx Regulations

Regulations on sulfur oxides (SOx) were strengthened in 2020, setting forth a limit of 0.5% or less for the sulfur content in fuel oil used by vessels in general. We have addressed this issue with the use of fuel compliant with statutory regulations and installation of SOx scrubbers on large vessels. The sulfur content of exhaust gas released after filtering with the scrubber has been found to be less than the regulation level, contributing to mitigation of air pollution by vessel exhaust.

SOx scrubber installed on one of our large vessels

Image provided by: WARTSILA

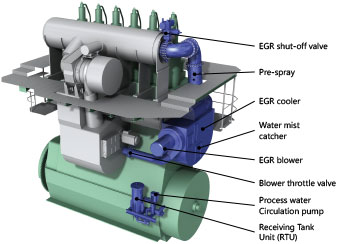

Response to NOx Regulations

Regulations on nitrogen oxides (NOx) stipulate limits for the NOx content in vessel exhaust by the year of keel laid. In response to this requirement, our new vessels are equipped with systems for exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) using urea as a catalyst, in order to comply with the tertiary regulation.

EGR system installed on our new vessel

Image provided by: Mitsui E&S Machinery Co., Ltd.

Climate Change Actions

To fight climate change, we aim to achieve carbon neutrality. To this end, we have set medium-term and long-term goals, which involve fuel conversion and other challenges to overcome going forward. At present, we are focusing on GHG emissions reduction, calculating GHG emissions and disclosing the data for the purpose of monitoring and improving activities.

Medium-term goal

25% reduction in annual GHG emissions

by 2030 compared to 2019 level

Long-term goal

Achievement of carbon neutrality by 2050

- Disclosure based on TCFD recommendations

- Calculation and disclosure of CO2 emissions (understand current situation and link to reduction activities)

Ongoing initiatives

- Ammonia-fueled vessel project

- Joint development project for vessels with hard sails

- Trial use of biofuels

- NSU Conducts the Second Biofuel Trial on a Rail Carrier

- NSU Conducted a Biofuel Trial on VLOC

- NSU Conducted the Third Biofuel Trial

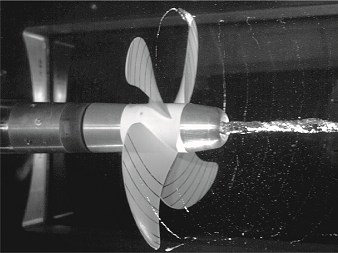

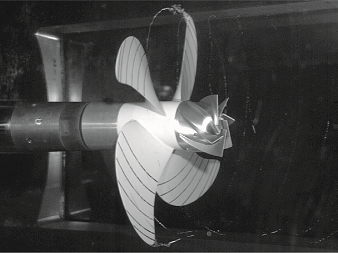

Replace with energy-saving propellers

Propellers installed on ships are generally designed to provide optimum performance at normal engine output. On the other hand, in an environment where the ship is navigated at reduced speed to reduce CO2 emissions, fuel consumption can be reduced by replacing the propellers with energy-saving propellers that match the power output. We have converted replaced the propellers of two of our managed vessels to with energy-saving propellers.

Removal of old propellers Replaced with energy-saving propellers

ECO-Cap

The water flow from the propeller creates a vortex called a hub vortex behind the propeller cap. This vortex creates a force pulling backward, causing energy loss. By installing a finned propeller cap designed to prevent the vortex from concentrating at the end of the cap, the propulsive force is increased and fuel savings can be achieved. As an energy-saving device, caps (ECO-Caps) have been installed on two of our management vessels.

Regular Cap

Image provided by: Nakashima Propeller Co., Ltd.

ECO-Cap

ECO-Cap installed on our Management Vessel

Installation of a fuel-saving device (energy-saving governor)

The main engine speed is maintained at a constant level by a device called a governor. While the set RPM is maintained by increasing or decreasing the fuel injection amount in response to RPM fluctuations, the energy-saving governor allows some variation in the main engine RPM and maintains the fuel injection amount at a constant level, thereby reducing fuel consumption. Energy-efficient governors are being installed on our managed vessels as they become available.

LED lighting

We are gradually replacing the lighting of our management vessels to LED. In addition, lighting in the head office has also been replaced to LED. This reduces power consumption and CO2 emissions.

Environmental Education

Internal Education

We provide environmental education for employees as part of training for new employees and at meetings of each group. Programs for new employees focus on describing environmental management systems while those for group meetings are designed to share relevant information, including the agendas of Safety and Environmental Committee meetings. Additionally, in order to improve employees' environmental awareness, the Environment Conservation Promotion Group prepares and distributes original internal-use education materials related to environmental issues on a regular basis.

Education for crewmembers

For crewmembers of our managed vessels, onboard education programs are provided as part of on-the-job training (OJT) in addition to lectures on land. On shore, pre-boarding training and seminars hosted by manning companies (in-house seminars) are used to provide crewmembers with opportunities to build awareness of the importance of safe and efficient vessel operations and environmental protection.